Tools and Machines That Accompanying You in Fabric Business

The thought of establishing a company rather than working for the rest of our lives occurs to everyone at some time in their lives. Thinkers like this are welcome to read on. Let me share with you that you have a wide range of options when it comes to launching a new company from the ground up.

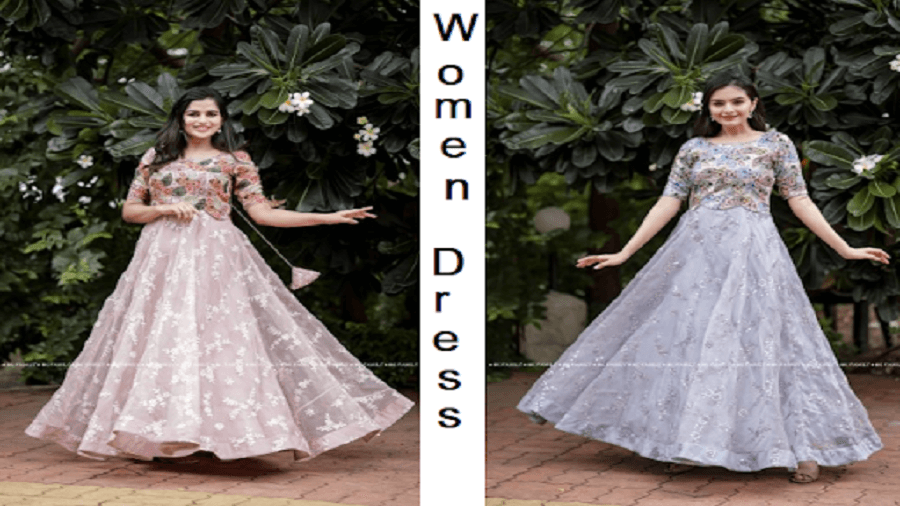

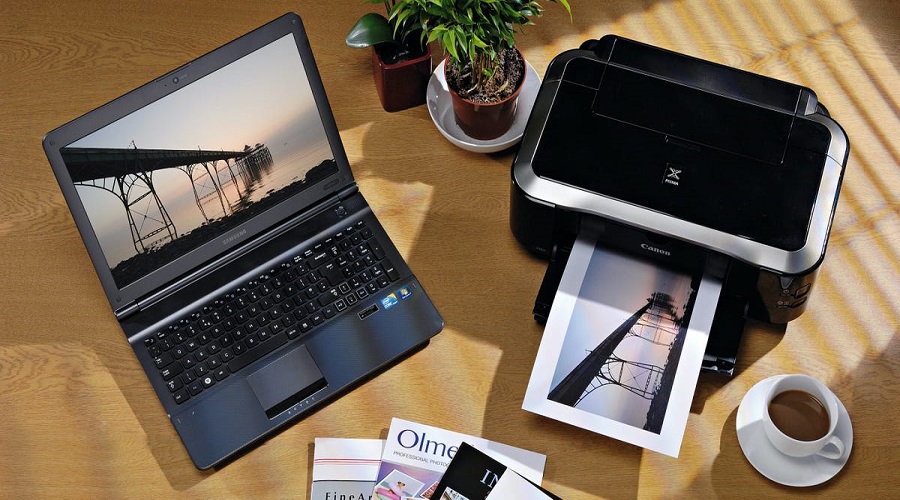

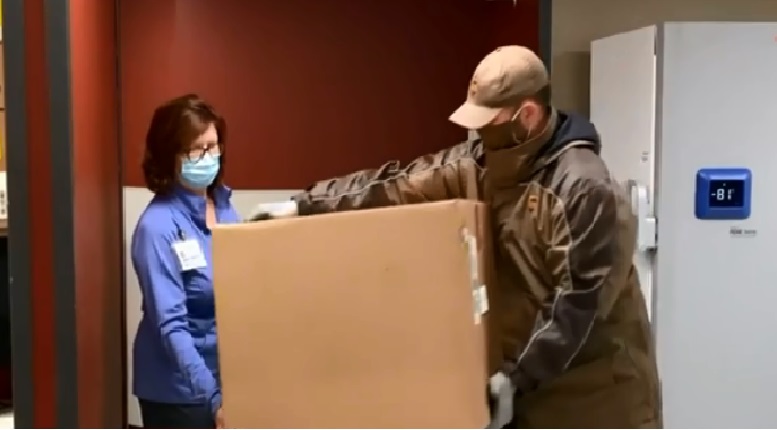

Starting a company in the textile sector is one of these viable options. It’s not a requirement that someone with prior expertise in the textile sector be the only one who can start a firm producing fabric materials. However, have you ever thought about how an industry manages to manufacture all of the goods we require? A final product is the result of using specialized machinery. The textile business uses a broad range of machinery to stitch textiles and produce clothing, carpets, and other textile products.

Here, you’ll learn about all the technology and equipment you’ll need to start a fabric production firm.

Let’s have a look at some of the most prevalent textile machines.

Machine for Yarn and Thread Production

A renewable resource like wool responds to variations in body temperature. When you’re cold, it works to keep you warm, and when you’re hot, it works to cool you down. Woolgrowers actively seek to conserve natural resources for future generations.

These woolen mill machinery is usable to produce yarn from wool. Wool is biodegradable, unlike synthetics. In order to make new blankets and wraps, you may utilize recycled wool.

Bleaching Machine

In the textile business, dyeing is a critical component. The dyeing sector performs a variety of cloth colors based on the needs of the consumer. The dyeing process helps in providing a uniform color and a level of durability and performance adequate to the long term usage of the ultimate product. Producers keep the substances to dye uniformly through this process. As long as various shades of the same hue are applicable, dyeing works.

Instead of coloring the fibers, crafters apply bleaching in order to get rid of the pigment and natural colors that are present inside them. It’s nothing more than a chemical treatment applied to the substrate’s inherent color. Woven and knitted cloth may be bleached as well.

Thread Winding Machine

For the most part, winding is applicable to transport yarn from one packet to another. Additionally, companies also use winding for the purposes of packing, clearing, and checking the yarn. Spools of thread are wound on these machines.

Scutching Machine

Manufacturers use these scutching machines to remove the cotton seeds from the fibers. To get cotton ready for spinning, one stage in the preparation process is scutching. Hand labor or the use of a scutcher machine are the most common methods.

Carding Machines

Carding machine is also famous as the “heart” of spinning. This removes the dust and grime from the fibers by opening them up to single strands.

Spinning Machine

A significant segment of the global textile market. Before a thread stitches together, it must go through spinning. These spinning machines spin materials like cotton into thread or yarn. The thread or yarn may be knitted or woven together to make a piece of cloth.

Yarn Gassing Machines

These devices are designed to remove extra fuzz and intensify the color. Also producers use it to warm the fiber as a Bunsen burner.

Conclusion

I hope from this post, now you have some basic idea about fabric manufacturers and textile industry. With these machines, manufacturers create excellence level fabrics whether it is voile cotton fabric or silk fabric dress or polyester georgette fabric. Thus, you develop your own fabric business with the help of these machines and equipment.