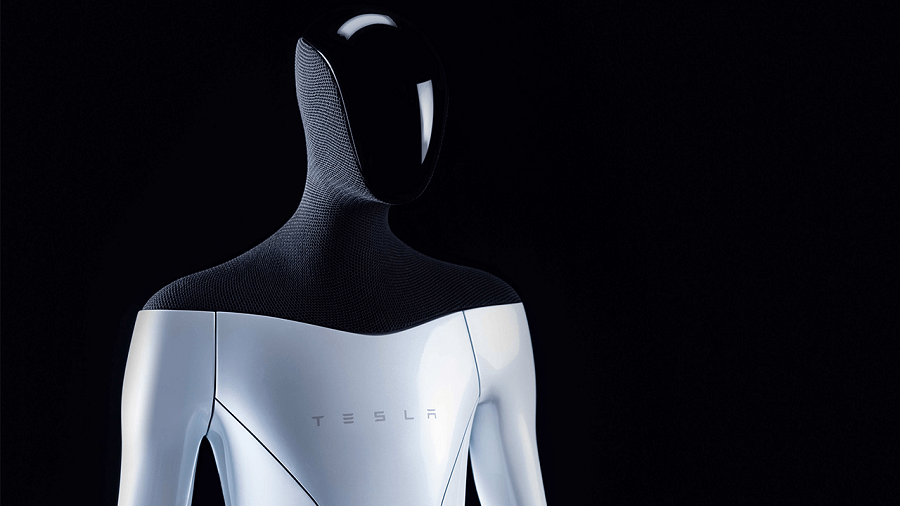

Tesla Announced Remarkable Production at its Gigafactory in Nevada

Multiple news outlets reported that Gigafactory Nevada is a joint venture of Tesla and Panasonic. This facility is currently manufacturing battery cells. They previously used this factory to manufacture battery packs for its electric vehicles developed at Fremont Factory. Tesla also manufactures stationary energy storage products and electric motors including Powerwall and Megapack.

Moreover, Vice President Chris Lister left Tesla when he was Operations in charge of the Nevada Gigafactory until the summer of 2022. The facility name now changed to the name of the senior director of vehicle operations and production engineering, Hrushikesh (Hrushi Sagar). He directly reports to CEO Elon Musk and is also in charge of the Fremont Factory.

Meanwhile, Gigafactory Nevada staff participated in a meeting to discuss the future of this plant, in September 2022. Sagar also confirmed that Gigafactory Nevada effectively manufactured around 283,473 drivetrains in the 2nd quarter of 2022. Tesla’s Fremont and Austin facilities utilized most of those power trains to manufacture vehicles.

The Production of 8,800 High Voltage Battery Packs

However, the senior director stressed that the production facility will continue manufacturing top-quality products. The factory will reportedly make a balanced production of 8,800 high-voltage battery packs per week. He added that it would keep making vehicles with supplied packs to Fremont Factory. It is important that Tesla has significantly improved Megapack production at the factory.

The automaker also reported per week manufacturing capability of 42 giant Megapacks, an increase from the previous quarter of 34. The vehicle manufacturer also claimed that it effectively manufactured around 37,600 vehicles in the 2nd quarter. But the facility now has the manufacturing capability of at least 6,500 Powerwalls per week. Tesla would supposedly reach over 70,000 Powerwalls per year with the quarterly output.

Gigafactory Nevada Considers Fremont Factory as a Client

Moreover, the management of Tesla also discussed the Fremont Factory during the meeting. Sagar said the Gigafactory Nevada seeks to consider the Fremont Factory as a client. Tesla is currently manufacturing 12,000 vehicles per week at the facility and constantly working to improve to reach around 14,000. He said all of these results are impressive and show more dedication.

The Gigafactory Nevada of Tesla currently produces around 300,000 drivetrains in each quarter, which is important in the company’s success. The automaker announced plans for a bigger 70 MW rooftop arrangement at Gigafactory Nevada in 2017. It has now become the largest production facility in the world with a wider margin.

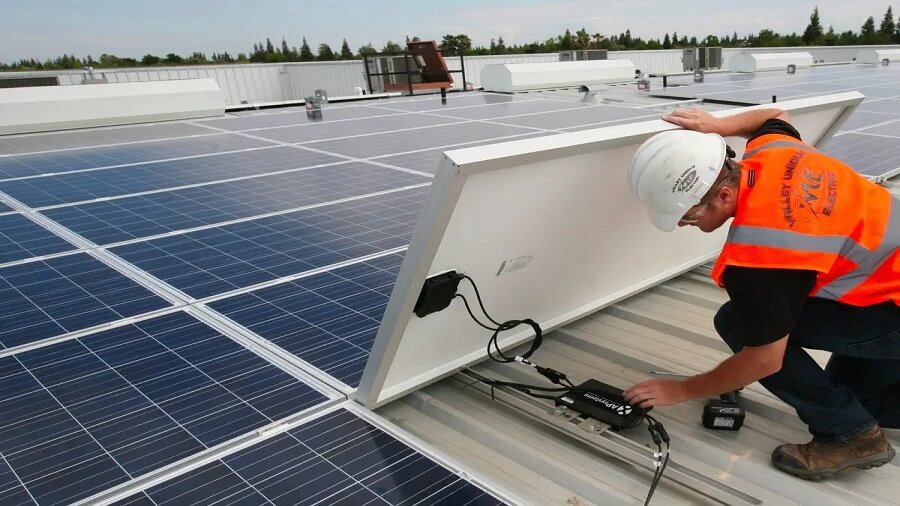

Tesla has Deployed 3.2 MW at the Manufacturing Factory

This project was supposedly found crawling for a long time. Tesla finally began manufacturing the solar arrangement in 2018. The company worked hard to expand the project over the next few years. But the project didn’t mark the growth size Tesla often discussed. Tesla said last summer that the company has deployed 3.2 MW at the manufacturing facility.

Tesla also modified its objective to deploy 24 MW rather than 70 MW on the rooftop of the production factory. However, it is now even smaller in size compared to the original plan. The company believes it is supposedly enough to bring the largest rooftop solar power deployment. Keep in mind that there are much larger solar farms out there than 24 MW power.

The Automaker is Constantly Expanding its Production Facility

However, Tesla is distinctively discussing rooftop solar arrangements but not ground-mounted arrangements. After a couple of months, the company has presented a significant amount of progress after adding more MW of solar power. The new installation is also visible in new satellite images of the Tesla Gigafactory in Nevada. But it is hard to consider the actual capacity the company has deployed.

Meanwhile, it looks like the company has made a considerable improvement over the past couple of months. The company is constantly expanding the size of the facility for a long time. The factory is manufacturing a large number of battery cells, packs, and drivetrains for Tesla. But the massive structure has stopped at 30% completion for the past 4 years.